TPE Basics: Thermoplastic Elastomers and the Blow-Fill-Seal Process

As soon as there are special demands on the elasticity and compressibility of a container, the blow-fill-seal process is often chosen. Therefore, the focus is on products and ideas that are user-friendly and cannot be realized with alternative materials in an ideal way. The special feature: The forces needed to deform or empty a container are much lower than with comparable processes. The technology thus skillfully exploits its advantages and is enjoying increasing popularity on the market.

Until now, many manufacturers who used the blow-fill-seal process resorted to PE or PP. However, the new material solution from KRAIBURG TPE allows them to benefit from all the advantages of the elastomer, including simplified procurement and the ability to custom-make the TPE exactly for the required application.

How does BFS processing work?

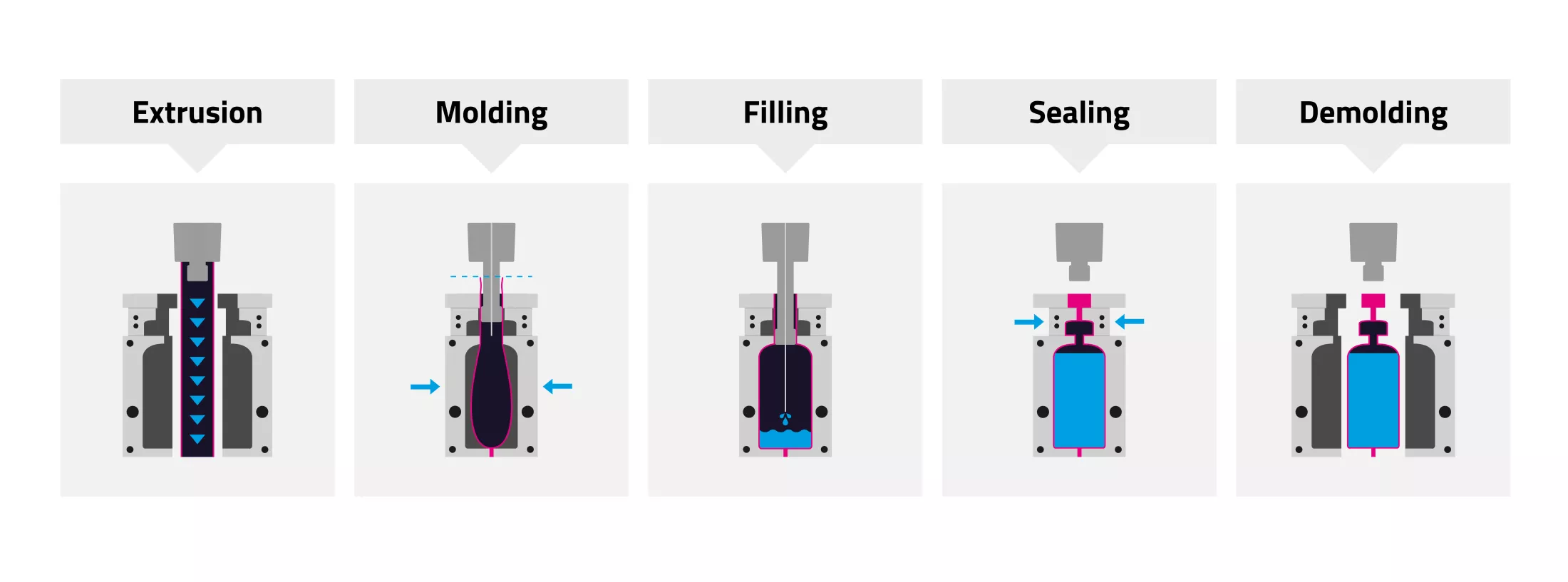

The manufacturing process using the technology combines several steps of aseptic drug manufacturing into one system. In the first step, a tube is extruded from the thermoplastic elastomer in the form of plastic granules and taken over by the blow molding tool. The mold simultaneously closes, squeezes and welds the bottom of the tube. A mandrel retracts and inflates the hose to form the molded part. Vacuum can also be used.

The filling material is also aseptically filled into the mold via the mandrel. The mandrel moves out of the mold and the container is aseptically sealed with the desired closure system via a mold jaw. The mold opens, the container is removed and the process starts again.

All this is achieved in one process without human intervention. This is a standard procedure for the production of infusion bags, eye drops in disposable ophtioles and other dosage forms.

Do you have any questions about the process or our TPE solution?

Please feel free to contact us directly!

Autor | Oliver Kluge

Market Segment Manager Medical Applications at KRAIBURG TPE

Phone: +49 8638 9810-479

E-Mail: oliver.kluge@kraiburg-tpe.com