The Littfield solution - A kitchen helper with many tasks thanks to Controlled Migration from KRAIBURG TPE

In (professional) kitchens, the stove is often not the only thing cooking. "Good tools, half the work" is the motto, even when preparing food. The focus of kitchen hand tools is on user-friendliness as well as durability. Soft skills also play a decisive role: appearance, haptics, recyclability and extended utility. This is exactly where Littfield's kitchen helper succeeds, offering an alternative to spoons, spatulas, ladles and dough scrapers.

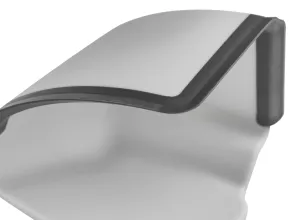

The rotating ladle spatula "Made in Germany" consists of two components, is made of polypropylene with 30% glass fibers and is BPA-free. The highlight: the soft pull-off lip made of plastic from KRAIBURG TPE. This add-on puts the tool in the top class of kitchen aids, because it can be used to clean the pot wall almost completely. This avoids the unnecessary throwing away of food residues and makes cleaning much easier. A novelty in this segment!

The Littfield helper complies with all legal guidelines on food contact. The tool is currently available on all European Amazon marketplaces, Littfield Amazon Store and soon via the online store at littfield.de.

The material used is ideally suited to the target application and meets all the necessary regulatory requirements ex works. The cooperation worked very well, both with local plastics processor Eftex and with Littfield itself. Together, we were able to bring a kitchen aid to market that is very well thought out. Both the customer and the processor received on-site support from KRAIBURG TPE - we are of course happy to make this possible.

Dirk Olberding, Market Manager Consumer

"KRAIBURG TPE has supported us in our journey from the very beginning," said Robert Lehmann, managing director of Littfield.

"Initially, we only had the design and the basic idea of a combination of hard and soft components in order to optimally master the challenges required. From that point on, we brought KRAIBURG TPE on board and were supported throughout the process, including the material selection of the hard component and process implementation. The result is a product for a highly competitive market with a great USP that puts us ahead of competitor products," concludes Lehmann.

The controlled migration compounds used are particularly suitable for applications that come into contact with fatty foods. They also have a very low migration potential. TPEs in this range are also suitable for injection molding as well as extrusion processes, cover a wide hardness range and impart a soft, velvety feel.

Autor | Matthias Wagner

Head of Sales Consumer EMEA

Phone: +49 8638 9810-267

E-Mail: matthias.wagner@kraiburg-tpe.com

Dirk Olberding

Market Manager Consumer

Phone: +49 8638 9810-511

E-Mail: dirk.olberding@kraiburg-tpe.com

The FC/CM2 series is your material solution for fatty food contact applications. It has an extremely low migration potential. The compounds are available in translucent and can be colored.